Ultrasound Solutions offers sonotrodes-transducer technology to prevent the growth of algae, mussels and sea pockets on vessels.

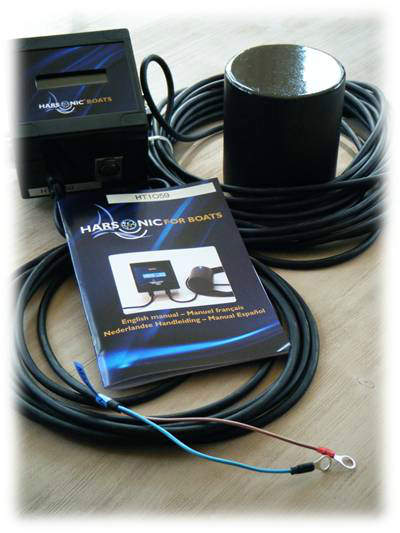

The company’s ultrasound-driven, low-capacity sonotrodes prevent biofilm from cultivating on chests, pipes, filters, pumps, box coolers and hulls.

Low-capacity ultrasound solutions for cleaning vessels

Since 2008, lower freight rates have forced ship management companies to prolong the operational life of vessels. Most antifouling solutions are built for sailing and not anchors. Depending on water temperature and salinity, hull and cooling systems can be overtaken by growth, resulting in docking issues and high repair costs.

Ultrasound Solutions’ systems have been developed to prevent fouling on fuel and power-related systems, as well as biofilm cultivation on hulls, cooling systems, and water and fuel tanks.

Ship ballast water management systems

For ballast water management, a new ultrasound reactor is currently under development and will be available until late 2017.

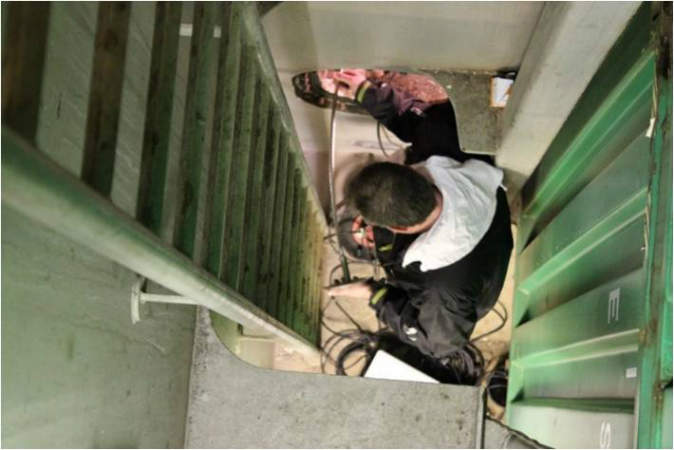

The system will be installed in vessel engine or pump rooms, offers a capacity up to 5,000m³, and fulfils International Maritime Organization (IMO) and US Coast Guard (USCG) regulations.

Ultrasound Solutions provides service and installation strategies to customers in order to determine the optimal location of its easy-to-install solution on-board vessels.

About Ultrasound Solutions

From its headquarters in Diessen, Germany, Ultrasound Solutions offers long-term, professional consultancy services and state-of-the-art solutions to international customers.

In 2015, the company established its first East Coast department in Redding, Connecticut, US, and intends to expand to the Far East following the development of its new ballast water management system.

Ultrasound Solutions recently founded a new ultrasound competence centre, and collaborates with leading research centres to develop new systems.