Valcom designs, develops and manufactures measurement and control instruments in the marine industry on ships and in offshore applications. Almost 40 years of experience and continuous efforts in researching and developing innovative solutions make Valcom the ideal partner as a supplier of measurement and control equipment for several applications.

Valcom monitors the level of ballast, cargo and service tanks, measures the pressure on manifolds and inert gas control, detects the temperature in tanks and survey operations, such as cargo load with high and overfill system, and monitors the presence of oil mist in cargo or pump rooms.

Valcom products have obtained type approvals from the main international audit institutes and are sold directly, as well as through distributors all over the world.

Screwed, flanged and submersion pressure and level transmitters

Valcom produces the 27 series transmitters in a number of different materials, such as AISI316, titanium and Hastelloy for the marine environment. Different styles include screwed, flanged and submersion, which cover a wide variety of couplings for new or existing installations. Many thousands of units are installed on service tanks, ballast tanks, draft measurement, cargo tanks, IG pressure, vapour line pressure, cargo line manifold, ballast pumps and line pressure.

Pressure and level transmitters with Smart Hart characteristics

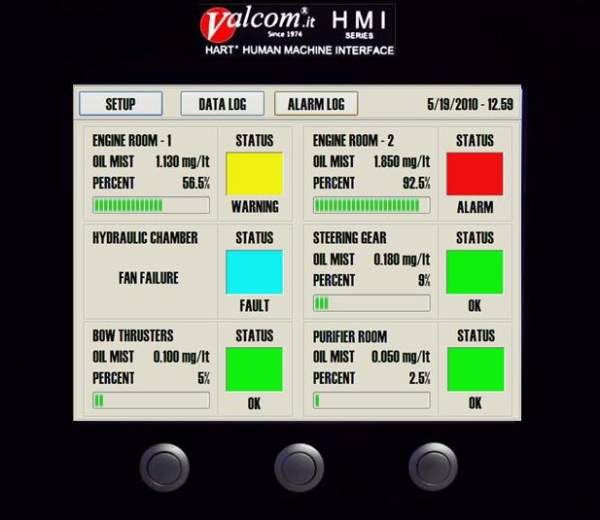

The T7 series of pressure and level transmitters work in the same applications as 27 series but with Smart Hart characteristics. They can be connected to our HMI unit, which collects signals, can perform remote calibration, alarm functions, volume and level display, as well as retransmit via TCP/IP or Modbus to the operator station. Other functions are also available upon request.

Ultrasonic liquid level switch for sea-going vessels

The ultrasonic liquid level switch ASL400 is constructed for the on sea-going vessels and in industrial plants. This pure static sensor works on the principle of distributed acoustic waves in a metal rod.

During its life, the ASL400 needs no adjustment. Sensitive piezo-ceramic components and electronics are placed on the top of the sensor, not in direct contact with liquids, but perceive the liquid presence through acoustic waves propagated inside a metal rod. This helps to reach extreme working temperatures (-200°C – 200°C) and pressure limits (vacuum – 400 bar).

The ASL400 allows the customer to check the system easily. Each sensor, required to be checked before filling the tank, can be surveyed without any opening of the housing, by pressing a test button, installed on the sensor housing either locally by hand or through a pneumatic piston remotely actuated or simply through a magnet.

Atmospheric oil mist detection system

OMD is an atmospheric oil mist detection system for marine and offshore applications, developed for installation in machinery and pump rooms, as well as commercial, naval and ro-ro ships, as requested by international IMO regulations.

OMD oil mist measuring is based on the physical principle of optical scattering. Infrared light emitted from a LED is received from two photodiodes for measure and reference purposes; by the comparison between the photodiodes output, the presence of oil mist can be detected.

The detector is calibrated by the manufacturer with a certified oil mist generator, as stated by IMO recommendations. OMD is based on digital electronics for signal analysis, including fault detection and photodiodes degrading monitoring system.

Two external bicoloured LEDs show the instrument functioning state and the alarm state activation. The external case of the detector is made of AISI316 St.St. and anodised aluminium alloy and the installation is performed with a mounting bracket. The VALCOM HMI DIGITAL HART acquisition system enables several OMD to be connected on the same pair of wires in a multidrop network configuration.

Bubbling system for level measurement

BMS is a bubbling system for level detection based on the measurement of hydrostatic pressure caused by the liquid contained in the tank. The working principle is based on the measure of the pressure value needed to maintain a constant and regular air flow through a pipe probe open in the bottom and submerged into the liquid.

At any level variation of the liquid in the tank corresponds to a variation of the hydrostatic pressure applied on the air outgoing from the probe pipe; these pressure variations are precisely detected by the 27 P/I converter and converted into a standard 4-20mA electric signal or HART protocol. PR3 regulator keeps constant bubbling air flow at any level value, assuring great reliability and accuracy.