Sir Meccanica SpA is a world leader in the production of portable machine tools.

Since 1991, the company has been producing tools for onsite operations, including in-line boring, overlay welding, flange facing, turning, drilling, and tapping. With all of its products, the company strives to achieve the fundamental principles of innovation, reliability, and quality.

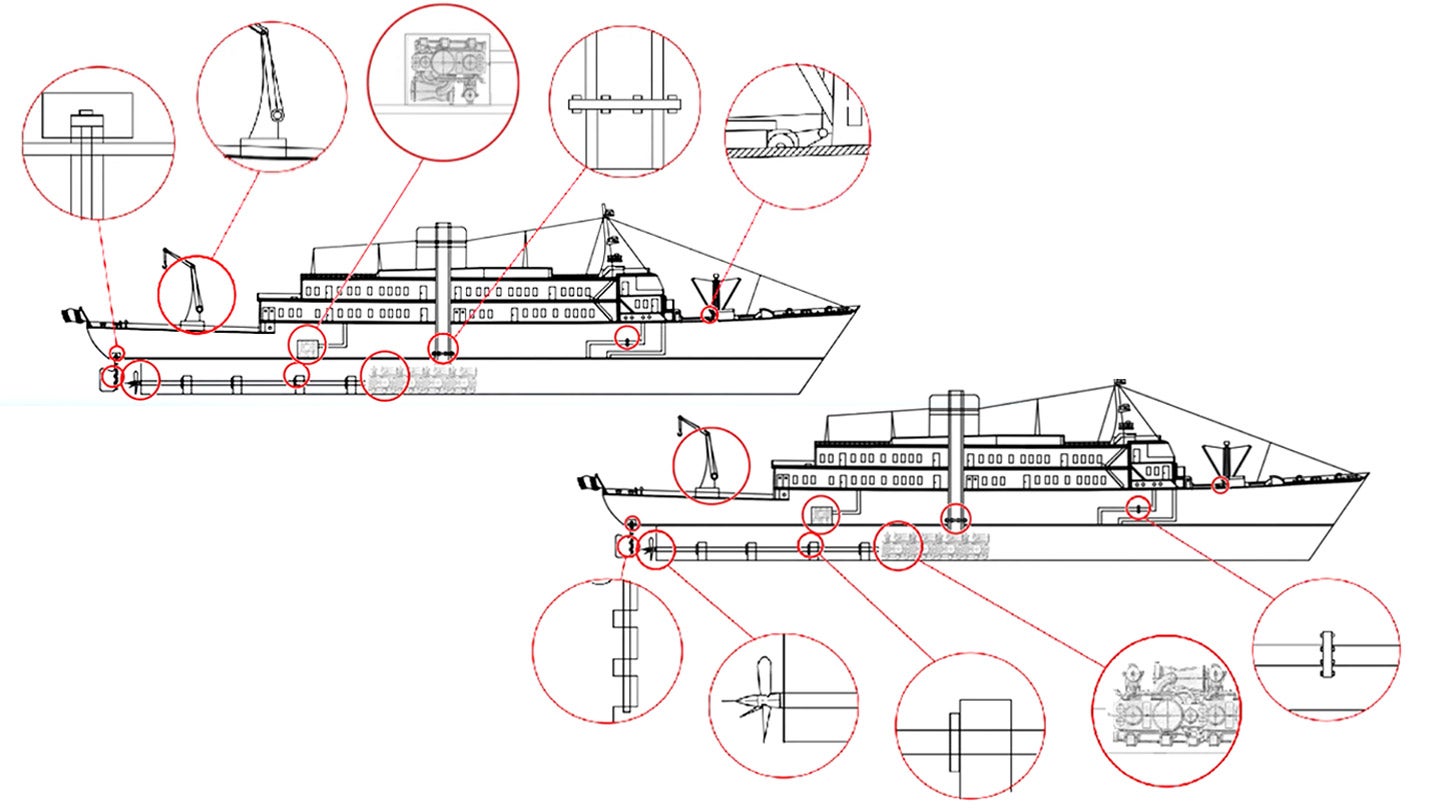

Sir Meccanica aims to meet its clients’ needs. As the shipping industry evolves, clients require more than a simple machine tool; clients need a customised tool that is specially designed for their needs. As experts in manufacturing, the company has created many innovative and revolutionary solutions for the shipping industry. Sir Meccanica aims to pass on its knowledge by providing customers with solutions that they can then integrate into their own production to improve processes and make them more efficient.

Customisable portable machine tools for the shipping industry

Sir Meccanica’s portable machine tools are easy to set up and can be used onsite to repair worn holes and heavy equipment articulated joints with extreme precision and reliability. The company’s tools are suitable for a variety of civil and naval maintenance, repair, and operations (MRO) and are used throughout the maritime and shipping industries. The portable tools are extremely useful for maintenance onboard ships, vessels, offshore support vessels, dry cargo vessels, cruise vessels, and bulk carriers. The portability of the tools also means that they can be used to repair machinery of any size.

Some key advantages of the portable tools include: the ability to perform onsite maintenance, an 85% reduction in down time, and no equipment disassembly is required. This means that transportation and labour costs are reduced, making the portable tools a more cost-effective alternative. The tools are also customisable, depending on customer requirements, meaning that there are more than 30 models of portable tools to suit a variety of machining operations and working diameters.

Every machine is powered by an electronic control panel that allows the operator to set and monitor both the rotation and the feed speed. The patented ESPS system avoids overloading the machine as a safety precaution in case any parameters are incorrectly set.

For the CNC machine tools, the control panel is enhanced by a touch screen display, with a user-friendly CNC interface. It allows the operator to execute manual and CAM created programs with ease.

Portable machine tool certifications

- UNI-EN-ISO 9001 Certification: application of rigorous procedures in the business management process.

- CE certification (N° IMQ 192): products conform to the safety prerequisites foreseen by communitarian directives.

- GOST Certification: products conform to standards for exportation to Russia.

- Nato Code (NCAGE AFA 74): official supplier of materials and services for the Government of the United States of America and of the American bases in Europe.

Maritime portable multifunction machine tools

The company’s line of portable multifunction machine tools includes the WS Series and the WS Series Full CNC. The WS Series of tools is suitable for:

- In-line boring (also on blind holes)

- Internal and external overlay welding (also on blind holes)

- Drilling

- Tapping

- Facing Bosses

- Creating Circlip Grooves

- External machining

The tools can be adapted for many different situations and eight customisable models are available, operating at sizes from Ø22mm up to Ø1700 mm.

Accessory equipment is also available for the tools, including:

- Semiautomatic Facing Head

- Motorised Facing Head

- Faces Welding Kit

- Electronic Positioning Display

The WS Series Full CNC line of tools is suitable for:

- In-line boring

- Overlay welding

- Curved shaping

- Conical machining

- Simple and shaped facing

- All types of threadings

- Chamfers

- Grooves

To suit a range of client specifications, six customisable models are available that operate at sizes from Ø100mm up to Ø1500mm. Accessories and kits are also available. These can be added to any machine to enhance or modify the operational capabilities, which further increases the tools’ flexibility.

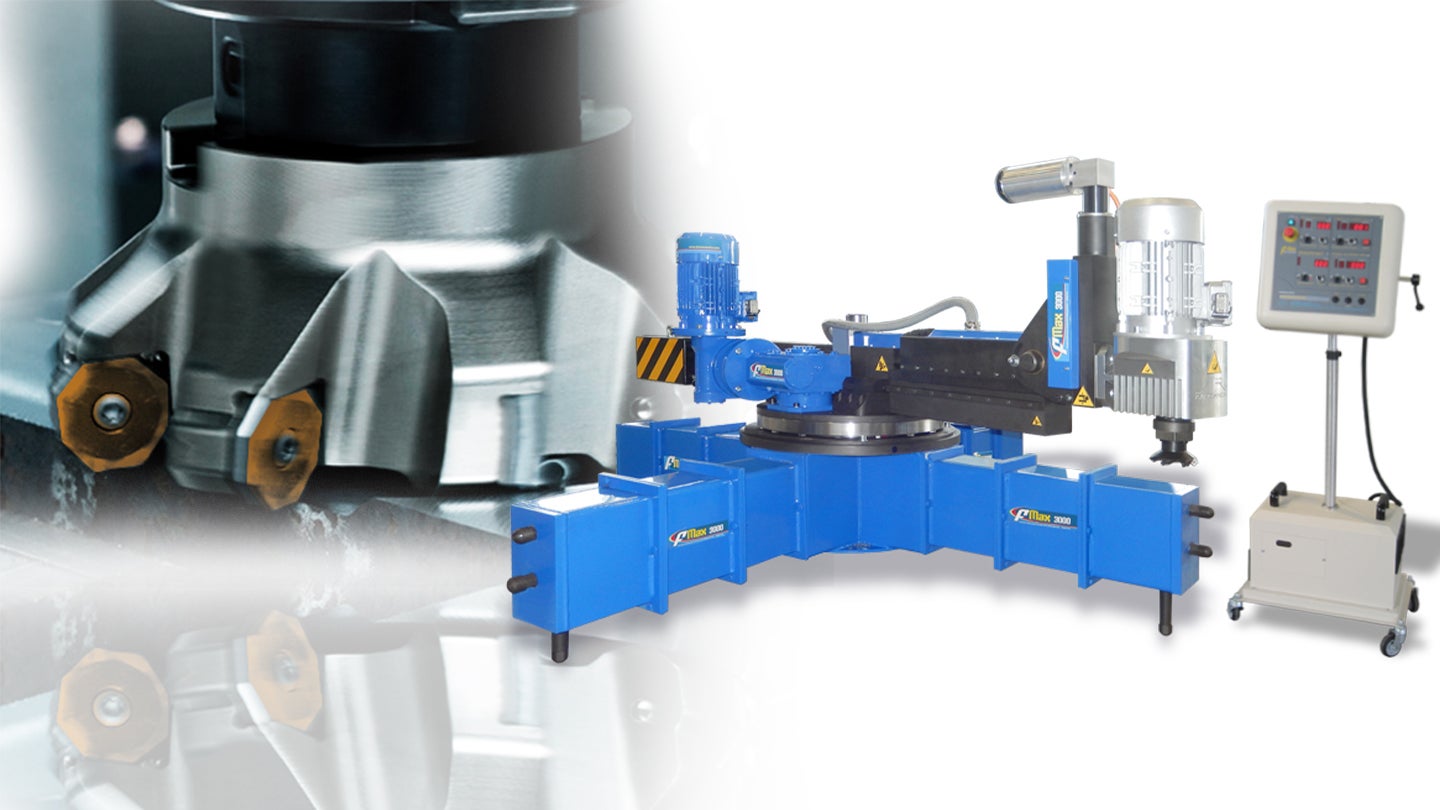

Portable flange facing machine tools for the shipping industry

In addition to its multifunction portable tools, Sir Meccanica also offers portable flange facing machine tools. The F-Max Series of tools can be used for:

- General Flange Facing

- Milling

- Boring

- Grooving

- Plunging

- Chamfers

In the F-Max Series, there are eight customisable models available that operate at sizes from Ø350mm up to Ø6000mm. A CNC version is also available.

To expand capabilities of the tools, accessory equipment is also available. This includes:

- Drilling kit

- Boring kit

- Circular pocket kit

- Tapping kit

- Overlay Welding kit

- Oxygen cutting kit

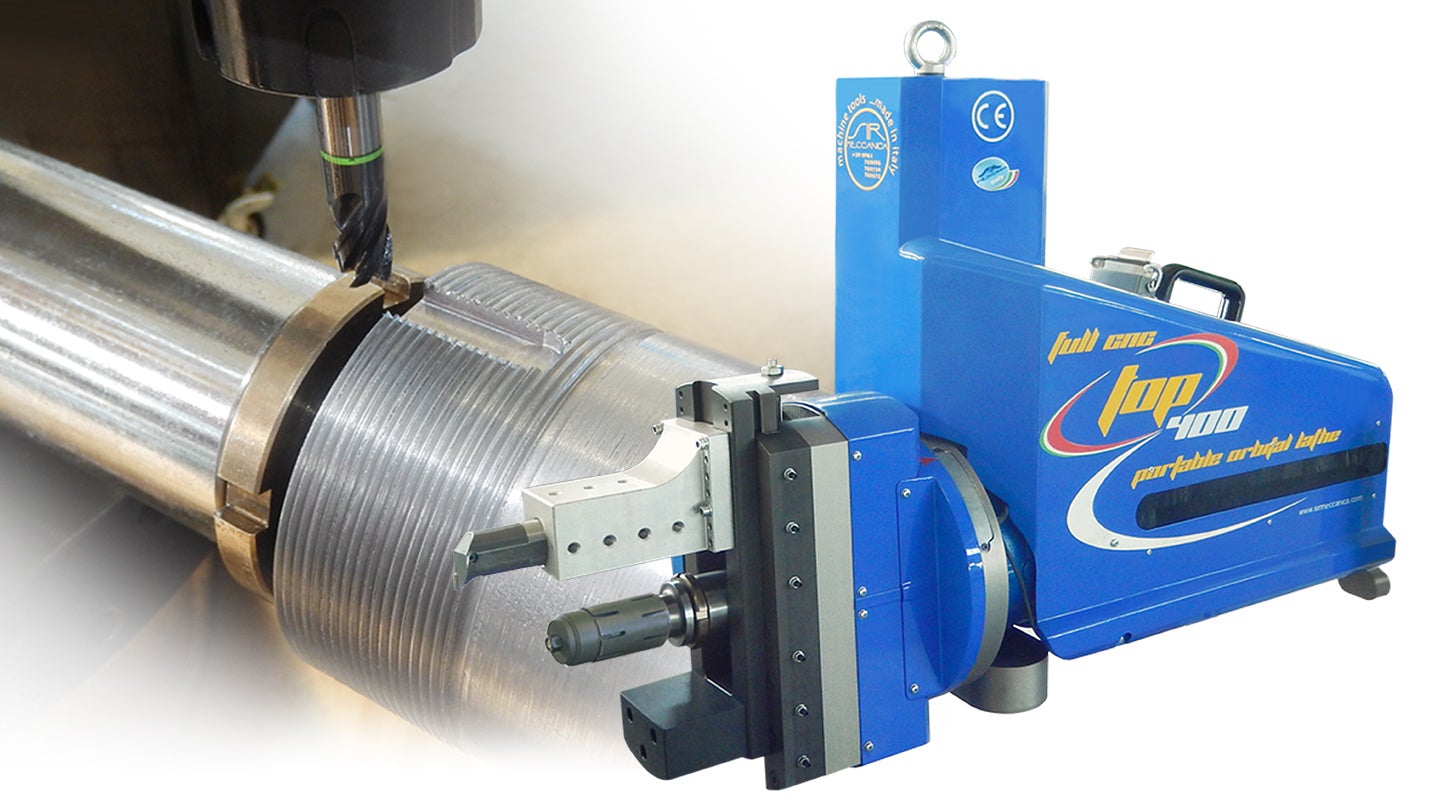

Portable orbital lathes for the maritime industry

The Top Series Full CNC line of portable orbital lathes is suitable for:

- All Geometric Profiles

- Standard and Tapered Threading

- Simple and Profile Facing

- Multilevel Cylindrical Grooves

Two different customisable models are available that operate from Ø0mm up to Ø400mm. Each machine can also be equipped with additional accessories or kits to expand the operational possibilities.