FullX: a top-entry valve for special requirements.

Our valve can be used in a variety of applications, offering many advantages. The HEROSE FullX can be individually planned and optimally installed in a vacuum-insulated system. It protects against unwanted rapid evaporation. The product is characterised by high internal and external tightness and is absolutely reliable with a long service life. The Top-Entry function enables quick and cost-effective maintenance that is carried out without vacuum losses.

Many possible applications make our FullX a real all-rounder

- Hydrogen When stored in liquefied form, temperatures of up to -255 °C are reached. The evaporation of hydrogen must be minimized to prevent losses. Our top-entry valve FullX, optionally with vacuum insulation, is designed for this application.

- LNG The FullX can be installed in the LNG sector, for example in LNG refuelling stations, vacuum-insulated pipelines or bunker stations. The FullX can be used to ensure that the LNG arrives at the desired location at cryogenic temperatures.

- Air separation unit The FullX can be used in an air separation units for storage and provision for extraction. Would you like more information about our valves in the air separation unit? You can find the flyer here.

The FullX can also be used in pressurised containers for helium, hydrogen, LNG and oxygen. It is also ideal for installation in refuelling systems in the aerospace industry and in cryostats.

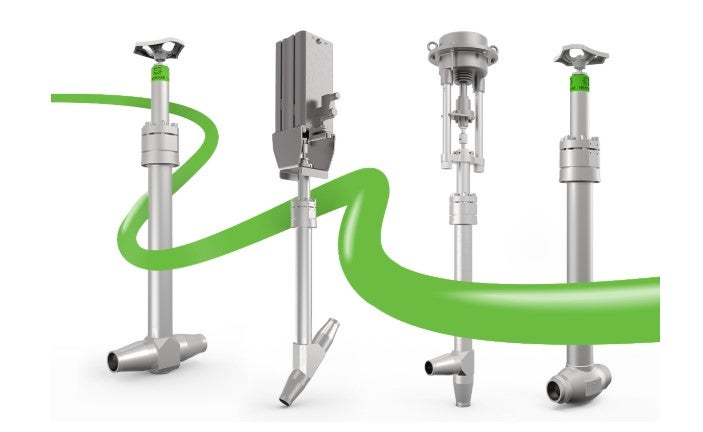

Our variations, your benefits

- Body made of solid or cast material

- Straight, Y- and angle-type body

- Bellows: top or bottom position

- Bellows monitoring

- Check function

- Control function

- Throttle function

- Purge port

- Fire-safe design

- TPED / TPER certification

- New collar with many advantages

- Thermical optimisation

- Extended heat input

Technical precision for safe use

- Sizes: DN10 – DN50

- Pressure: up to PN63

- Permissible operating temperature: -269°C to +80°C

- Connections: butt weld

- Material: stainless steel

- Approved media: hydrogen, air gases, steam and cryogenic liquefied gases incl. LNG

- Versions: manual, pneumatic actuation (diaphragm and piston actuator)