WRS Marine Inspections and Services, founded in 1994, is now one of the leading companies providing tailor-made services and products to ship owners and ship related companies worldwide, particularly hull damage assessment and repair.

HULL DAMAGE ASSESSMENT AND REPAIR

WRS Marine is certified by all major classification societies, and carries out surveys according to the guidelines given for assessment and repair of hull damage.

Ship owners or managers can reduce the costs of repairs by carrying out pre-inspections prior to docking.

Our services also include:

- Worldwide services during docking periods

- Assisting during steel repairs

- Ultrasonic surveying

- Cathodic protection

- Ultrasonic thickness measurement

HULL-CONDITION MONITORING

WRS can provide up-to-date information about the hull condition of your vessels, through class renewal surveys, ultrasonic surveys and cathodic protection of hull or ballast tanks.

In today’s world, there is a growing demand for a company that does more than just take ultrasonic readings. WRS is such a company.

Situated near Rotterdam, WRS Marine Inspections and Services has carried out surveys on behalf of ship owners and managers in shipyards all over the world.

DOCKING ASSISTANCE DURING REPAIRS

All shipping rules and regulations are, when altered, sent to our office, ensuring we are up-to-date with the latest requirements.

Our official reports hull-condition monitoring reports are made according to the latest applicable International Association of Classification Societies (ICAS) rules and accepted by all major societies. Reports can be submitted by either CD-ROM or hard copy.

In the case of a steel or visual inspection being required a report containing all relevant information will be submitted. This report will contain the locations of those items subject to visual inspections, e.g. pittings, groove corrosion, corroded spots, coating breakdowns, holes, fractures, indents, buckles, corrosion patterns, stress parts and knife edging.

All required photos of mentioned defects will be submitted in order to give the principal an idea of the situation at the site.

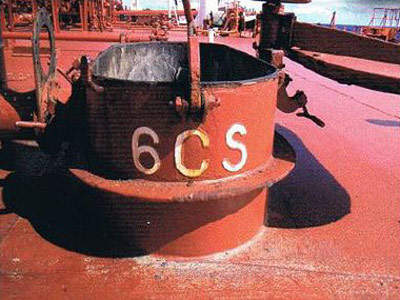

IMPRESSED CATHODIC CURRENT PROTECTION SYSTEMS

Technicians of WRS Marine have been involved in the development of Wilson Walton International’s systems of cathodic protection using impressed current (Impressed Cathodic Current Protection, or ICCP).

Developed over many years of practical experience, the latest version of the impressed current system employs the best hull units and electrical equipment available.

The impressed current systems incorporates anodes, reference electrodes and a transformer-rectifier power unit. Whilst the foregoing protects the hull structure, it is also important to protect the propeller, exposed shafting and the rudder.

The propeller and shafting are grounded to the hull structure with a shaft slipring, making them electrically common with the hull, and the rudder is also grounded with a flexible cable. With electrical continuity established these components are protected by the impressed current system.

WRS Marine technicians service all types of impressed systems worldwide.