Goltens Green Technologies provides ship repair services in order to keep vessels in operation.

The company enables owners to confidently evaluate, design and install the most appropriate solutions to address environmental regulations, while minimising downtime and interruption to operations.

Leveraging heavy investments in technical knowledge and the latest laser scanning and design technology, Goltens Green Technologies delivers turnkey solutions to address a wide array of environmental compliance challenges.

Whether an owner is addressing sulfur emissions control or ballast water treatment challenges, the company has the experience to help them select the right system and execute a well-planned and time and cost-efficient upgrade of their fleet.

System selection for regulation compliance

Goltens provides new technology to address current and future international regulations.

The company is an experienced, independent partner that assists clients with confusing regulations, technological solutions, looming deadlines, and the need to efficiently coordinate implementation across a fleet of vessels.

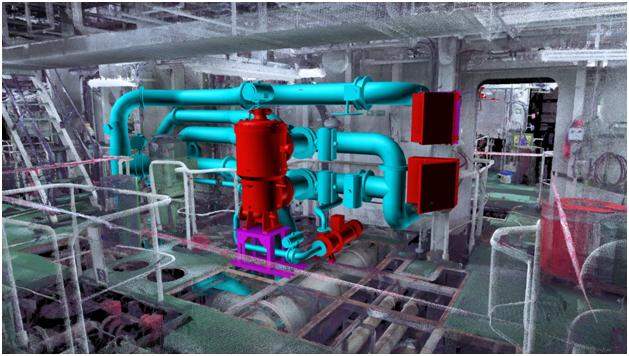

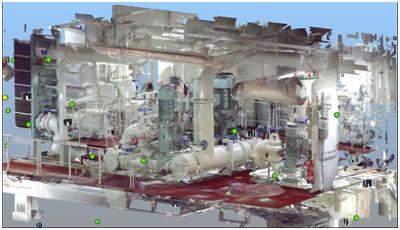

Laser scanning for measurement on ships

Laser scanning provides an incredibly accurate and efficient solution for determining the feasibility, impact and conflicts associated with installations on ships.

It also eliminates most of the risks associated with manual measurement and fabrication on-board, without prefabrication.

The laser scanner’s accuracy of +/-2mm enables precise measurements and the creation of highly detailed 3D images of the engine room or other spaces.

The scanning usually takes less than a day, and does not disturb the vessel’s operation or require the crew to vacate the area.

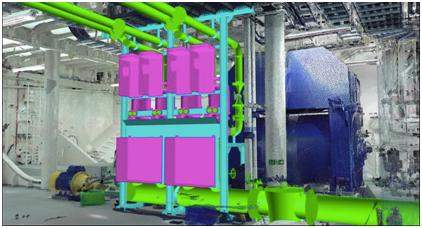

Modelling and concept design

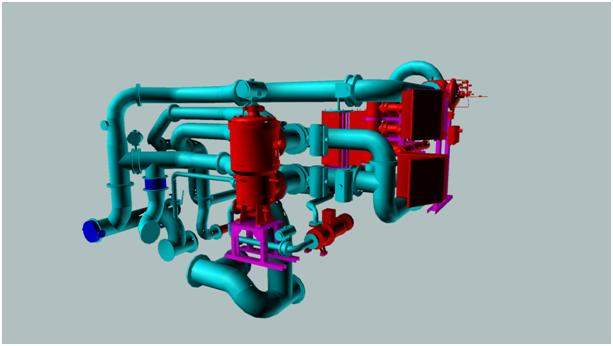

The results of the scan are fed into a 3D computer-aided drafting (CAD) programme to model shortlisted systems into the existing space on vessels.

At this stage, chief engineers and shipowners can see how the system will fit, and voice their thoughts and suggestions before any further actions are taken.

Goltens Green Technologies’ experts will then evaluate options for implementing their requests.

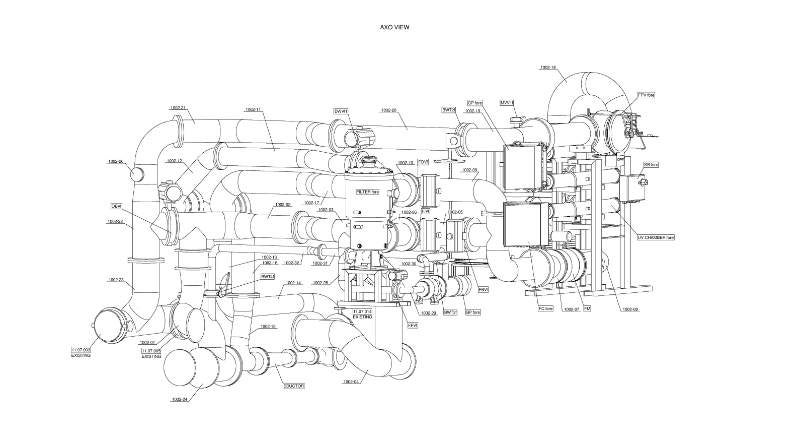

Detailed ship engineering

Due to the high accuracy of the 3D laser scanner output, it is possible to make an equally precise production package with drawings that include all foundations, mechanical and electrical components directly from the scan results, along with a comprehensive overview of all the parts needed for an installation.

The accuracy of the process makes it possible to prepare a complete kit, ready for installation.

Pre-fabrication and installation

Goltens Green Technologies delivers a detailed material list with its engineering design services. This provides shipowners with a complete production package that can be installed by the company or another shipyard of their choice.

The list also helps keep track of costs by projecting a realistic price estimate, based on the materials needed.

Ballast water treatment system retrofits

Goltens Green Technologies offers retrofits for ballast water treatment systems (BWTS). It has undertaken more than 100 projects using systems from leading manufacturers.

Sulphur emission compliance solutions

The company offers a range of different solutions to comply with sulphur emission limits that vary greatly in terms of complexity and costs, and all require a careful analysis of a wide range of factors.

These solutions range from changing the type of fuel used to cleaning the exhaust gases prior to discharge from the vessel.

Dual fuel retrofits of diesel engines

In close cooperation with market-leading manufacturers, Goltens Green Technologies retrofits diesel generators with dual fuel capabilities.

These retrofits involve the installation of complex piping and control systems, following a scanning and design process that increase the accuracy and speed of the implementation.

Reverse engineering for ships

Goltens Green Technologies carries out reverse engineering to create complex models for risk mitigation that can be integrated into detailed engineering for upgrades and modifications.

Reverse engineering is typically applied for compound curvature of hulls and propellers.

Piping renewals and databases

Goltens Green Technologies creates detailed isometric drawings of piping systems and prefabricate pipe spools to dramatically reduce installation time.

The company’s database contains details on vessels’ pipework, so it can be prefabricated at the location of choice. This is very beneficial for vessels with excessive wear and tear on their piping systems.

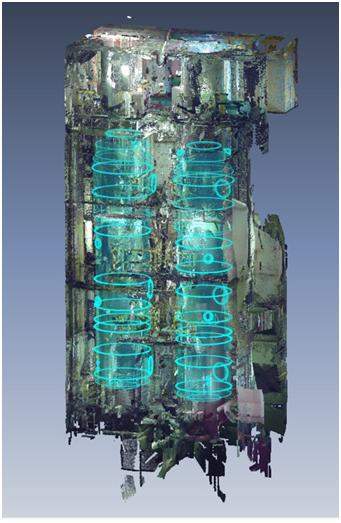

Scanning and modelling for rigging operations

Goltens Green Technologies uses scanning and modelling to determine the optimal routes for machinery movement and removal, with minimal disruption and hull cutting.