Clearwinner Innovation is one of the UK’s leading manufacturers of marine (MGO and HFO) fuel additives, supplying to all aspects of marine operations, from workboats to deep sea vessels.

Additives to increase marine fuel lubricity

Clearwinner Innovation’s product range address a number of diverse issues and problems that operators may face with the fuel they have been supplied.

From January 2015, IMO limits set a diesel fuel sulphur content of 0.1% for vessels operating in emission control areas (ECAs), with a highly optimistic global cap of a fuel sulphur content, set at 0.5% by 2020, subject to a feasibility study.

But the trend does clearly indicate that at some future point, the intention is that all shipping should be burning diesel fuel (MGO) refined to this specification.

In the past few years, one of the principle concerns repeatedly voiced in the marine industry has been worries about the detrimental effect low sulphur fuels will have on components and component longevity.

Sulphur content in the fuel provides natural lubricity, which is an important built-in feature of diesel fuel, providing sufficient and continued ‘oiliness’ needed to lubricate fuel pump components and injectors.

Vessel operators should be aware of fuel additives on the market that incorporate lubricity agents, which are not harmful to the environment and are designed to replace the beneficial effect of sulphur content on components.

Sulphur in diesel fuels is removed from the fuel, as a result of the refinery’s hydro-treating process.

Treating diesel fuel with CLEARWINNER HYDROS LA 88, at a 1l HYDROS LA88 to 4t of MGO treatment rate does, at fractional treat cost, contribute to improving low-sulphur fuel’s poor lubricity characteristics. The required reduction in component wear and the additional protection given to fuel pumps and injectors takes immediate effect.

CLEARWINNER HYDROS LA88 also acts as a highly effective, non-abrasive fuel injector cleaner, maintaining optimum fuel injection and atomisation, improving fuel efficiency and ensuring a complete fuel ‘burn’. These factors all help to further reduce fuel consumption.

In addition to CLEARWINNER HYDROS LA88, other CLEARWINNER products are available to address these other relevant problems:

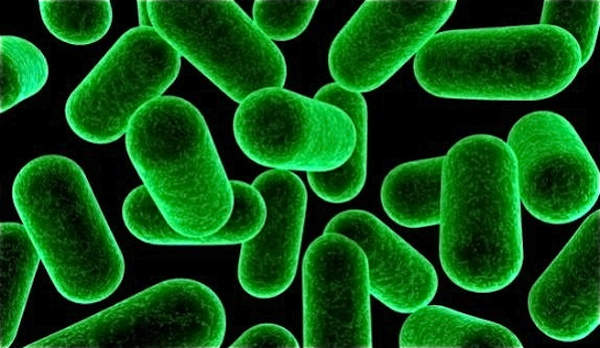

- Microbial growth in fuel (diesel ‘bug’): CLEARWINNER D-BUG

- Diesel antiwax / antigel cold flow improver: CLEARWINNER CFI

- Heavy fuel oil treatment: CLEARWINNER SLUDGEBREAKER

CLEARWINNER D-BUG: Diesel fuel biocide

Should Diesel ‘bug’ strike , evidence of which is shown through experiencing blocked fuel filters and poor engine performance, a treatment into the fuel storage tank of CLEARWINNER D-BUG Diesel fuel biocide rapidly (within 24h-48h) eliminates the manifestation.

A dosage rate of 1l D-BUG to 4t of MGO provides a sufficient ‘kill’ rate: as a preventative maintenance product, CLEARWINNER D-BUG may be applied at a dose rate of 1l D-BUG to 10t of MGO.

CLEARWINNER CFI: Diesel antiwax and coldflow improver

Where vessels are operating in regions where severe winter and subzero conditions are prevalent , it is recommended that even Winter-grade MGOs be treated , for additional protection, with a diesel coldflow improver.

CLEARWINNER CFI, dosed to the fuel at a treat rate of 1l CFI to 1t of fuel will improve the fuel’s existing Cold Filter Plug Point (CFPP) by a further -10°C.

This additional flexibility in flow properties could be crucial to a vessel’s ability to operate, particularly in cases where the fuel storage tanks may be situated close to , or next to , the ship’s hull and when external temperatures , may have greater effect on the fuel.

CLEARWINNER SLUDGEBREAKER: Heavy fuel oil treatment / asphaltene dispersant

SLUDGEBREAKER is an HFO fuel treatment, designed to disperse asphaltenes, reducing sludge formation by up to 70%.

It is designed to promote complete fuel combustion and maintain optimum turbo charger and economiser efficiency. Applying SLUDGEBREAKER to HFOs also results in cleaner storage tanks, reducing maintenance and cleaning costs.

A treatment rate of 1l SLUDGEBREAKER to 10t of fuel brings a fractional treatment cost resulting in the above benefits, ultimately creating a reduction in fuel consumption by up to 3%.