FRIENDSHIP SYSTEMS is a leading provider of advanced software and services for the maritime industry, specialising in ship hull optimisation, hydrodynamic design, and simulation- and data-driven workflows. With decades of experience in naval architecture and marine engineering, the company delivers innovative solutions to improve vessel performance, reduce fuel consumption, and meet modern environmental and regulatory standards.

Ship hull optimisation

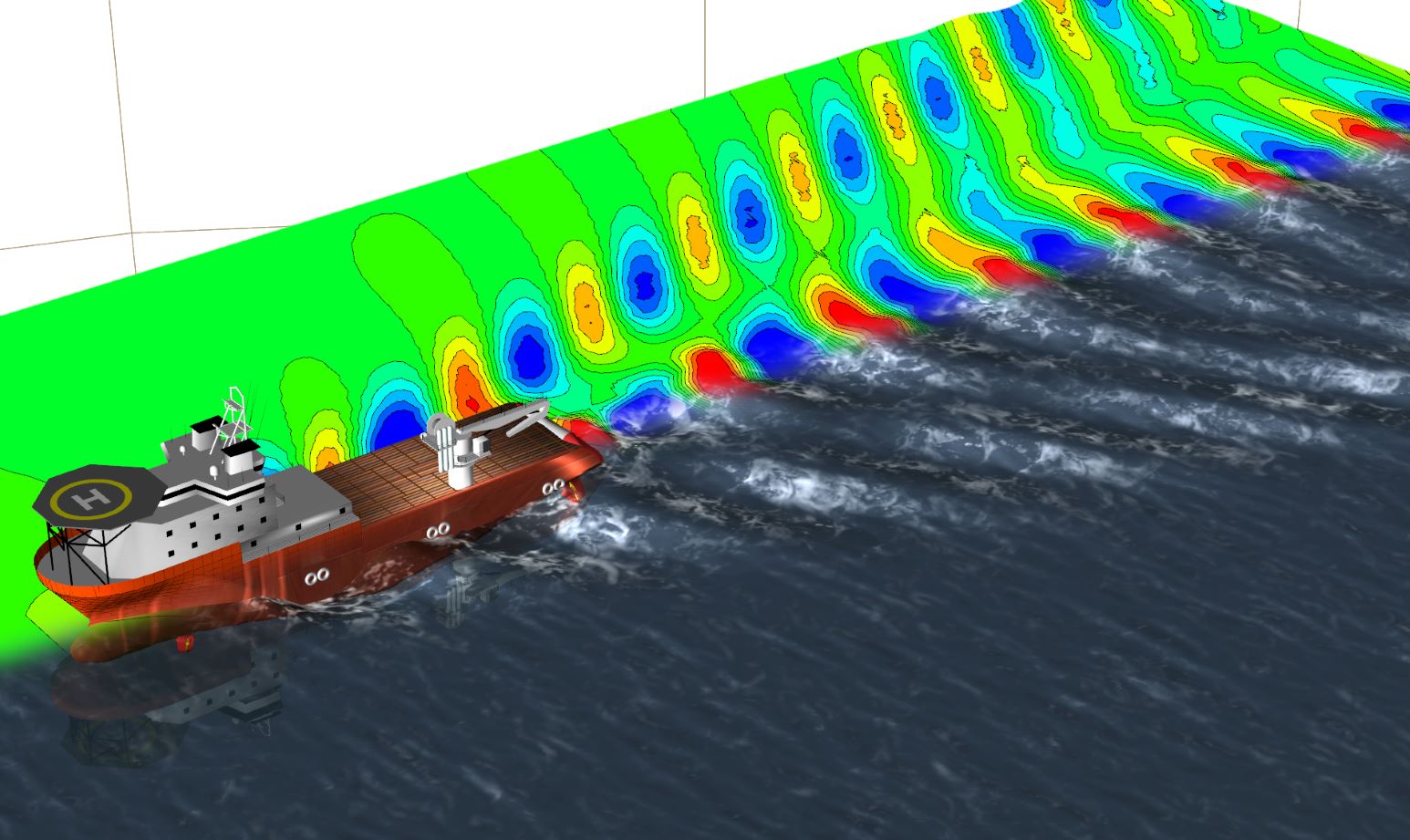

FRIENDSHIP SYSTEMS aims to help engineers and designers maximise the efficiency of ship hulls by optimising not only the shape of the vessel, but also every element of a vessel that interacts with water. This can be achieved by reducing drag, optimising propulsion, and improving the overall hydrodynamic performance for real-world operational conditions.

With its flagship software platform, CAESES, FRIENDSHIP SYSTEMS creates a single cohesive workflow and automated design process that uses parametric modelling, optimisation strategies, and computational fluid dynamics (CFD). Ship designers can use this to explore a wide range of hull variants and make informed, data-driven decisions during the design process.

Personalised design and consulting services for the maritime industry

In addition to software, FRIENDSHIP SYSTEMS offers consulting services to assist customers with complex design challenges. Its clients include marine equipment manufacturers, design offices, and shipyards, and FRIENDSHIP SYSTEM’s experienced engineers can support customers with a range of tasks, such as:

- Custom parametric modelling

- CFD workflow integration

- Development and training of AI models for data-driven decision-making

- Shape optimisation for hulls, propellers, and appendages

These services are ideal for companies looking to improve development, solve specific performance issues, or build internal competence with simulation-based design.

FRIENDSHIP SYSTEMS serves a diverse client base throughout the marine industry worldwide, including leading shipyards, model basins, classification societies, equipment manufacturers, and academic institutions. The company uses a combination of powerful technology and a thorough understanding of marine hydrodynamics, geometry control, and real-world design constraints.

Prominent users of FRIENDSHIP SYSTEMS’ solutions include:

- Commercial shipbuilders

- Yachting and racing vessel designers

- Offshore and naval engineering firms

- Energy and propulsion technology providers

The company’s solutions have been applied to all major vessel types, from large container ships and LNG carriers to offshore supply vessels, tankers, ferries, and performance yachts.

A comprehensive approach to marine design

FRIENDSHIP SYSTEM’s key advantage is its comprehensive approach to ship hull optimisation. Instead of treating geometry generation and simulation as separate stages, its approach joins them into a unified design environment. This enables:

- Rapid creation and variation of hull forms

- Integrated hydrostatic analysis and resistance prediction

- Full control over geometry parameters for sensitivity studies and optimization

- Compatibility with high-performance computing (HPC) for large design spaces

FRIENDSHIP SYSTEMS also collaborates with all major commercial and open-source CFD providers, offering clients maximum flexibility with their simulation tools.

Marine design optimisation

While hull design is a key part of its focus, FRIENDSHIP SYSTEMS also supports the design and optimisation of:

- Propellers and thrusters (including unconventional designs)

- Appendages and energy-saving devices (such as rudders, pre-swirl stators, and boss cap fins)

- Large marine engine components, such as turbochargers, piston bowls, ports, and manifolds

CAESES allows highly customised parametric models to be created for each component type, allowing engineers to perform automated simulations and make data-informed design decisions across the vessel system.

Sustainability and digital transformation in the maritime industry

As the maritime industry faces increasing pressure to decarbonise, reduce emissions, and operate more efficiently, ship hull optimisation is becoming a strategic priority. FRIENDSHIP SYSTEMS is at the forefront of this shift, helping organisations leverage digital tools to design greener, smarter ships.

With CAESES and expert consultancy services, FRIENDSHIP SYSTEMS provides clients with the tools and knowledge needed to meet IMO targets, reduce fuel consumption, and drive innovation.

About FRIENDSHIP SYSTEMS

FRIENDSHIP SYSTEMS is a trusted partner, helping clients to modernise design workflows, optimise new hull forms, or assist with simulation-driven projects. For more information about how advanced automation, integrated CFD, machine learning, and expert support can transform maritime design capabilities, contact FRIENDSHIP SYSTEMS using the form at the top of the page to learn more about its software and consulting services for ship hull optimisation.