Norsky was delivered by Aker Finyards 18 months after the contract was signed, and began service in July 1999. Norsky is owned by Bore Shipowning BV and chartered for eight years by P&O North Sea Ferries. Both parties had an input in the design of the vessel. The vessel is deployed on P&O’s Teesport to Zeebrugge service.

Norsky was followed in the Autumn of 1999 by a sister vessel, the Norstream, which was destined to be deployed on the same service as Norsky.

The vessel flies the Netherlands flag and has Lloyd’s Register classification.

DESIGN

Norsky has been designed to provide flexibility and maximum freight capacity, both for its current operator and any future deployment. Reflecting this, the vessel has exceptionally high deckroom on the main deck level, enabling P&O North Sea Ferries to optimise its double-stack ro-ro container transportation method. Clearance on the main deck is 7m.

Deck scantlings and the vessel’s general sturdiness reflect the provisions made for a lifetime of transporting industrial exports in Northern Europe. The vessel has also been built to Finnish-Swedish 1A ice class requirements, and has received the relevant notation from classification society Lloyd’s Register.

Norsky contains the equivalent of 2,630 linear metres on three decks, corresponding to a full load of 210 trailers. Norsky features a split stern ramp and has dispensed with the mezzanine deck sections seen in earlier ships. Cargo access is provided by a MacGregor designed system based on twin, 16m long axial stern ramp/doors at main deck level. The wider starboard ramp caters for traffic to the main and tanktop levels, while the narrower port ramp feeds freight to a fixed ramp leading up to the weather deck. Transfers to the lower hold are by way of a ramp leading down from the aft part of the main deck.

Norsky has a deck load rating for 120t on 40ft mafi-type trailers at main deck level, and has the ability to transport 100t loads in the lower hold, with a headroom of 5m.

Access to the upper deck level via the 7% gradient ramp on the port side imposes a 5m headroom limitation. On the upper deck, maximum load is limited to 55t for trailers, but the design of the area is also conducive to lo-lo working of container stacks up to 60t. Freight stowed on the weatherdeck gains a large measure of protection from the seas by way of the forward superstructure and also the raised bulwarks. The latter meet the height requirements of the chemical industry.

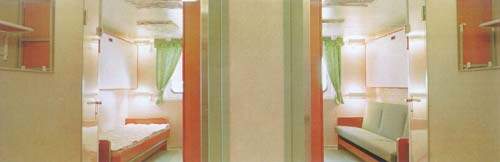

The vessel has a fully Dutch crew of 14 and, in addition to crew quarters, has six two-berth cabins for commercial drivers. Given the shortness of her current trading pattern, these are not likely to be used often under the current charter.

PROPULSION

Norsky is propelled by two medium-speed Wärtsilä NSD 46-series C nine-cylinder engines. Each gives an output of 9,450kW at 500rpm.

Drive is through reduction gears to a pair of controllable pitch propellers. Each gear has a power takeoff for a shaft generator, dimensioned for 1,200kW at 1,500rpm. The shaft alternators, covering electrical energy requirements at sea, are complemented by two Caterpillar 3508B diesel generator aggregates yielding 856kW at 1,500rpm. A pair of Kamewa 1,100kW thrusters built into the foreship section improve the vessel’s manoeuvrability.

The vessel’s propulsive equipment gives Norsky a service speed of 21 knots.

Norsky’s bridge control operations feature the Ship Control Centre (SCC) concept developed and engineered by STN Atlas Marine Electronics. The 55-2 integrated navigation and command system (Nacos) has been installed. One of the features of the Multipilot workstations that has been encompassed by Nacos 55-2 is the ability to superimpose radar and ARPA on to the electronic chart.