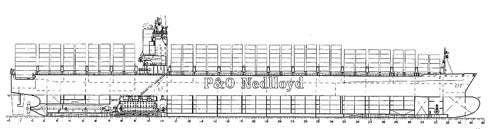

The P&O Nedlloyd Tasman is the first of five sister vessels built for P&O Nedlloyd by Kvaerner Warnow Werft (KWW), based in Warnemünde, Germany. According to KWW, the vessels were the largest ever to have been built in Germany. The containerships have a deadweight of 67,902t and can carry 5,468 TEU, including 500 refrigerated containers. P&O Nedlloyd Tasman was delivered in January 2000 and was to be joined by its four sisters by the end of 2000.

Due to restricted construction space at KWW, two of the series were to be built at Aker MTW in Wismar to the KWW design. The first of these two, the P&O Nedlloyd Mercator, was handed over by Aker MTW in March 2000 and the second was delivered in August 2000.

P&O Nedlloyd has also ordered four larger 6,788 TEU vessels from Hyundai Heavy Industries in South Korea. These vessels are scheduled for delivery from the end of 2000. Each vessel in this series will be equipped with 710 reefer slots and have a service speed of 25 knots.

P&O Nedlloyd Tasman flies the British flag and has Germanischer Lloyd classification.

P&O Nedlloyd Tasman is deployed on one of the Grand Alliance’s services between Northern European ports and the Far East.

DESIGN

The vessel has an overall length of 278.01m, a moulded breadth of 40m and a draught of 14m. P&O Nedlloyd Tasman is designed with eight cargo holds and 15 hatches. TEUs and FEUs can be accommodated in all 2,558 TEU holds and on-deck (2,880 TEU). All stacks, except the outer stack beside hatch 1, can be used for stowing all FEU containers. The hull has been designed to accommodate a variety of different loading conditions, including jumping loads. For this reason the holds are designed for container weights of 30t/TEU and 35t/FEU. Containers holding hazardous cargo can be carried on-deck, as well as in cargo holds. The cargo hatches are closed with pontoon covers made by MacGregor, stack loadings are 90t/stack TEU and 120t/stack FEU. The vessel can accommodate a total of 500 reefer containers: 350 on-deck and 150 in the holds.

The vessel is equipped with a Hitec integrated navigation system (INS) for one-man bridge operation, in compliance with notation NAV-OC, and with an integrated ship monitoring and control system (ISCM), also provided by Hitec. The two systems enable the crew to monitor and control all navigation and machinery operations from any of the workstation monitors on the bridge.

PROPULSION

Propulsion is provided by a single Sulzer 10 RTA 96C, supplied under licence by HHI, with an output of 54,946kW (74,700bhp) at an MCR of 100rpm. This is connected to an 8.4m-diameter Lips FP propeller.

Electrical power is provided by four sets of Mak 9M 25 diesel engines, each with an output of 2,200kW 6.6kV. The vessel is also equipped with one diesel-driven emergency generator, with an output of 330kW, 440kV. A STN shaft generator plant gives an output of 2,400kW, 6.6kV with a thyristor type frequency converter, and is able to operate in a range of 40% to 100% MCR.