Damen Shipyards Group is building two identical transshipment barges, referred to as Damen Crane Barge 6324, that are designed to handle ship-to-ship, ship-to-barge or ship-to-quay transfers.

The vessels will also perform harbour services, such as the transshipment of dry bulk, containers and break-bulk cargoes. The shipping company describes the barges as high-quality, reliable vessels that are easy to operate and maintain.

Both barges will be classified under Lloyd’s Register of Shipping as 100 AT, Pontoon and IWS.

The construction of the vessels began in June 2016 and, once built, the vessels will be stocked to ensure easy availability for prospect customers.

Design and accommodation details of the Crane Barge 6324

The barges have been designed using inputs from various departments of the shipbuilding company.

The transshipment crane barges will be 63m-long, 4.5m-deep and 2.5m-wide and will have a gross tonnage of 1,970t and deadweight of 1,720t. The scantling draft and design draft of the vessels will be 3.5m and 2.5m, respectively.

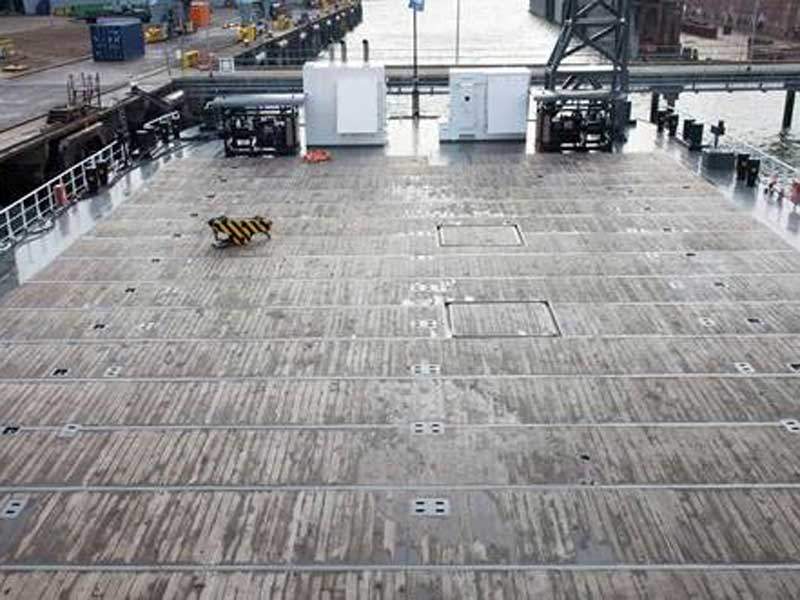

The vessels will include below a working deck area of 880m², including a 440m² area covered with fir wood.

The barges will also provide accommodation for 12 persons in cabins furnished with ventilation, air conditioning and heating systems. An office, a changing room, a recreation room and a fully-equipped kitchen will also be available on-board.

Equipment on-board Crane Barge 6324

The cost-effective transshipment barges will be equipped with a Liebherr CBG 350 crane. The rope grab crane will be capable of holding 35t of bulk cargo at a length of 36m during grab operation. During hook operations, the same crane will be capable of carrying 45t of bulk cargo at a rope length of 32m.

The crane will operate at a hoisting speed of 0-60m/min and 0-40m/min while holding 35t and 45t, respectively. It will increase the size of the rope from 12m to 36m in 63s.

The crane will require a nominal output of 345kW to deliver an average turnover of approximately 1,200t/hr. An extended cabin will be included on the crane to provide optimum visibility for the crane driver.

The vessel will include three towing brackets with a safe carrying capacity of 100t. The optional equipment will include a towing bridle, grabs and grab storage.

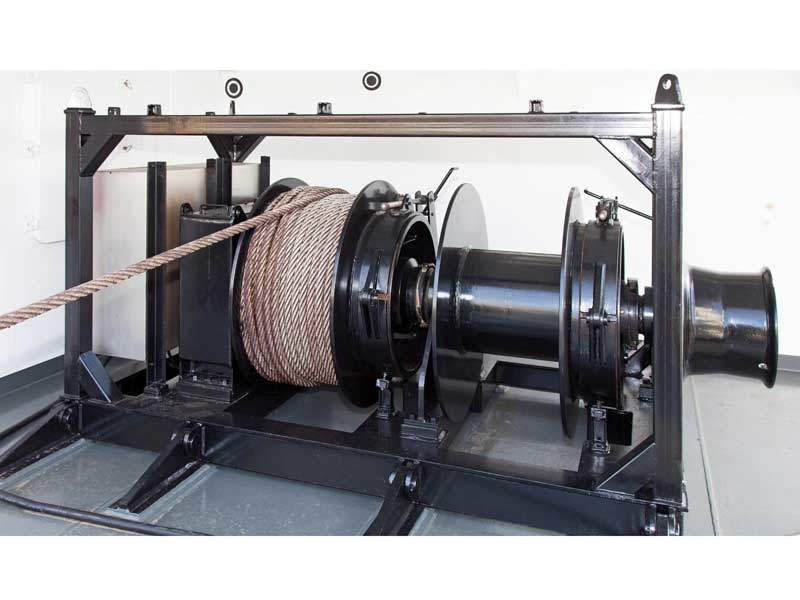

The on-deck mooring system will contain four DWT Electric double-drum winches and three anchors to provide maximum safety and stability during operations.

The hull of the vessels will be guarded by a combination of tyre fenders and third pipe steel fenders.

Each of the crane barges will include two inflatable rafts that are capable of carrying 12 persons. An inflatable dinghy with a davit will be optionally installed on the aft deck.

Tank capacities

The water ballast capacity of the vessels will be 1,760m³. Each barge will have the capacity to store 220m³ of fuel oil, 85m³ of fresh water, 80m³ of sewage and grey water, 5m³ of lubricant oil, 10m³ of dirty oil and 5m³ of bilge water.

Container capacities

The vessels will provide space for 70TEUs in two tiers on-board. The containers vary in size from 20ft to 40ft and will be handled with chains manually or through semi or fully-automatic spreaders. An option to install a container spreader will also be available.

Navigational equipment on the Crane Barge 6324

The navigation lighting and communication system on-board the vessels will be installed according to the classification.

Alternatively, the barges will also have an option to install navigation equipment on-board in combination with the optional thrusters.

Propulsion and power

The vessels can be optionally equipped with a Lloyd’s Register of Shipping class-assisted propulsion system, including two deck-mounted aft thrusters that generate a power of 323kW.

The auxiliary equipment will include two main and one emergency Caterpillar C-18 generator sets, each generating a total power of 545kVA at 1,800rpm. A Caterpillar C4.4 harbour generator will also be installed to deliver 119kVA power at 1,800rpm. The generator sets will be supplied by PON, while the electrical systems will be provided by Van der Leun.