Finnish ship designer Deltamarin has partnered with engineering company Gaztransport & Technigaz (GTT) to develop solutions for a fleet of LNG-fuelled vessels sailing on long ocean routes.

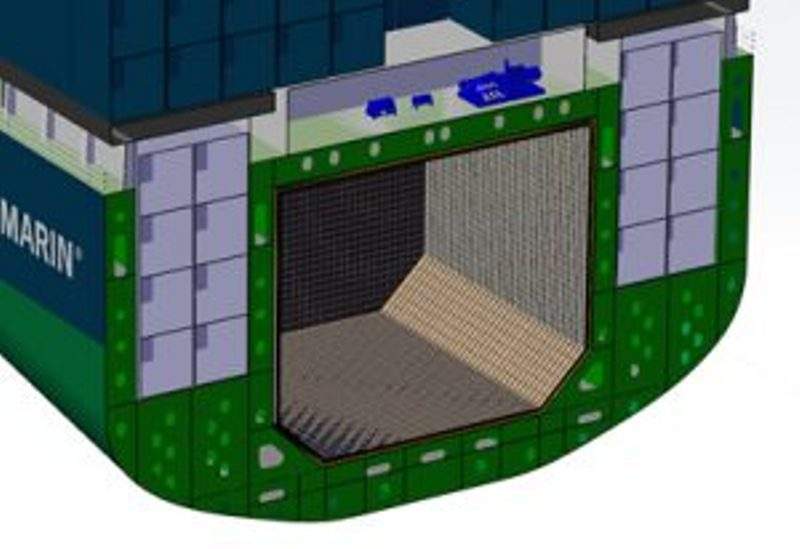

The companies have collaboratively developed the vessel designs with the goal of reducing the cargo space required by the systems compared to classic cylindrical-type LNG tank solutions.

The use of membrane-type tanks on cargo and passenger vessels was also studied as part of the project, which saw the creation of a container vessel, a pure car and truck carrier (PCTC) and a cruise ship.

Each of the ships involved in the project were equipped with modularised GTT membrane tank type solutions, which can be supplied in sizes ranging from 1,000m³-5,000m³ depending on the vessel.

The vessel is designed to be powered by either one or multiple tanks and its final fuel capacity is calculated by trading-off the rate between desired cargo capacity and bunkering intervals.

For instance, a container ship case vessel with a 2,500m³ tank provides an autonomy time of 22 days or can cover 10,000 nautical miles (nmi) to reach most of the intra-Asian, intra-European or intra-American trade destinations in a single bunkering operation.

How well do you really know your competitors?

Access the most comprehensive Company Profiles on the market, powered by GlobalData. Save hours of research. Gain competitive edge.

Thank you!

Your download email will arrive shortly

Not ready to buy yet? Download a free sample

We are confident about the unique quality of our Company Profiles. However, we want you to make the most beneficial decision for your business, so we offer a free sample that you can download by submitting the below form

By GlobalDataOther tank sizes such as 1,000m³, 1,500m³ and 2,000m³ are also capable of offering the same fuel capacity as the 2,500m³, but with less cargo space.

The project has also demonstrated that, on average, only around 60% of the LNG capacity provided by membrane technology could be accommodated in the same space when an optimised bi-lobe C-type tank solution is used.

Therefore, the membrane solution is found to have the potential to become the most feasible LNG fuel tank solution for ships with large fuel capacities.