As the maritime industry continues working to reduce its impact on the environment, after years of neglectful practices saw sometimes devastating effects on our ocean ecosystems, there are some issues that may appear to have been solved already.

One of these is the issue of ballast water, which was found to be carrying invasive species across the ocean, leading regulators and the industry to step in with the International Maritime Organisation (IMO) by developing the Ballast Water Management Convention.

Brought in by September 2017, the convention required vessels to begin installing ballast water treatment (BWT) systems and the BWT market quickly sprang up to address the new demand, but issues have now started to appear

Earlier this year, Ship Technology travelled to Copenhagen and met Bawat CEO Marcus Hummer, who made the surprising claim that many BWT systems are not fit for purpose and will lead to big problems when the IMO convention comes into full force on 8 September 2024.

Hummer later caught up with Ship Technology again to explain more about his claims, the state of the BWT market, and how Bawat is addressing the issues.

Noah Bovenizer: Can you introduce yourself and Bawat?

Marcus Hummer: My name is Marcus Hummer, I’m the CEO of Bawat, which is a Danish company focusing on Ballast Water Treatment. We do three types of businesses: we do installation on board vessels, we do mobile systems – mobile BWT systems – and then we do Ballast as a Service (BaaS), where we either receive untreated ballast water or deliver treated ballast water to vessels on a cubic metre basis.

We are located here in Denmark with branches across the world, including in the US, but listed on the stock market in Sweden as of two years ago.

NB: When we first met at Danish Maritime you made some interesting claims about issues with the current ballast water systems used by the maritime industry. What’s the state of play in the industry as we approach the full implementation of the IMO’s BWM Convention?

MH: In principle, as part of the convention, the different flag states have been asked to conduct testing and investigations on vessels under their own flag: How the equipment is working. in terms of biological testing. and what is being discharged?

Australia has done some testing, as have Singapore, Cyprus, and other countries, while Denmark has done testing that is not yet published. The overall conclusion is fairly clear that on an anonymous basis, without punishment, around 1/3 of vessels are failing.

And this is the message that we are trying to put forward, is that if you take that part and put it together with two other parts. One is that ship owners believe that as long as they have bought a type-approved system, then they’re alright, and that’s not really the case – as this is about what you discharge and not about what you install on the vessel.

The other is the fact that the port state controls have a legal obligation, partially already now, but definitely as of September this year, to check and investigate [ballast water discharges]. Then, how will the market react to this [discovery]?

We want to service this market because we believe that the market for ballast water can be served both in terms of installing technology on vessels and also by establishing the reception facilities – which we are in the midst of doing.

These work by receiving ballast water from vessels that cannot live up to the discharge criteria but also, in a reverse manner, actually loading vessels at their departure port with treated ballast water. So, when they come to their arrival port, they can simply de-ballast without treating anything.

NB: Bawat’s BWT system seems very simple, were you surprised that nobody else was doing it in the industry?

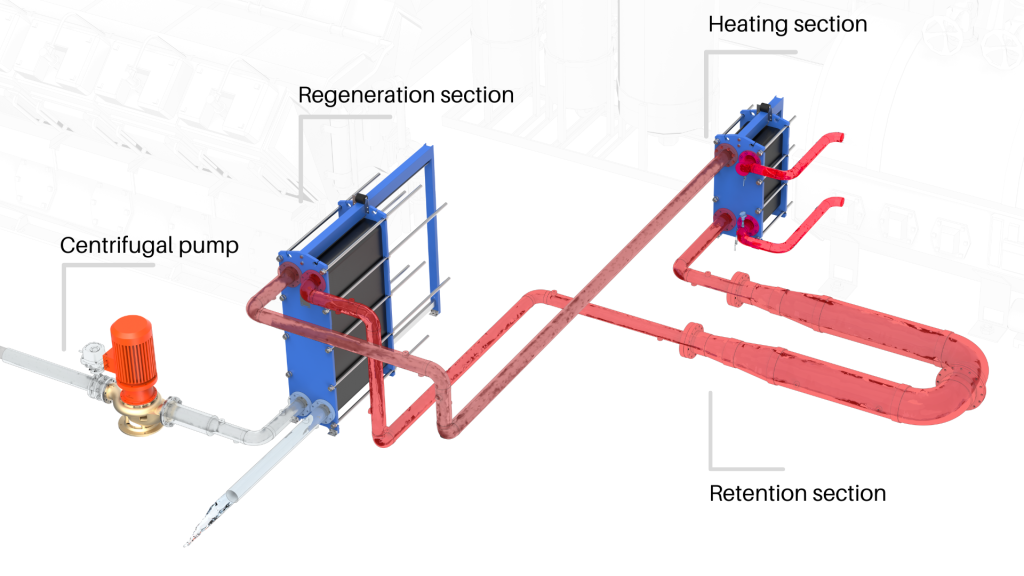

MH: Yes and no. We originally looked at a technology where we would introduce nitrogen to suffocate all the invasive species, and that worked on some of them, but not all of them. Then we came up with the idea that there was actually a lot of surplus heat, which we could use to retreat the water using heat to make sure everything was killed, In doing that, we found out that heat alone would do the trick.

That actually brought us in the direction of understanding that if you use heat alone, then you get a very simple system, because then you can do away with all the chemicals and all mechanical filtration. I would say the two biggest challenges in ballast water today, outside our system, are the mechanical filtration systems and filters, and the handling of a chemical system with a relatively unskilled labour force aboard vessels.

NB: With so many vessels allegedly not treating their ballast water properly, could you explain what you think the issue is with current systems which means the water is not treated properly?

MH: Looking at the information from the IMO’s experience building phase, the challenge is primarily the mechanical filters. These are filtering out what’s called zooplankton, which is basically the larger marine species, and the filters are basically a woven mesh. So, if they need to filter out something that’s maybe bigger than 50 micrometres, then the filter mesh would be maybe 40 micrometres.

The thing is that these zooplankton are not perfectly round, right? You could easily have a long zooplankton that is 200 micrometres long but only 10 micrometres in diameter, which will swim straight through your filter. So it’s the fundamentals of having a filter to take out the largest zooplankton that, to a large extent, is not working.

The second major issue is that if you’re using a chlorination system, you need to have enough chloride to kill everything, and that means that you create a surplus amount of chloride which you need to neutralise. But that neutralisation is not that simple, so you could end up putting out chemicals into the ocean, and you might still have the challenge that the filter in front of your chlorination system doesn’t work.

But these are facts that I would rather people took from the IMO’s experience building phase conclusions because my competitors will look at me and say: “Yeah, that’s because you don’t use chloride and you don’t use a filter.”

This is why it’s a delicate matter for us. We’d rather say: “We see the world from the experiment-building phase, independent from flag states saying there is a problem, and we are trying to say, okay, we have a solution for that.”

NB: As we approach the September deadline, do you think this will become a major issue? Or are ship owners likely to fix their systems in time?

MH: I have no illusions whatsoever that this will be solved in time, and I’m sorry to say that. It should be a major concern, but apparently it isn’t, since there is still a third of vessels failing.

So no, I don’t think it will be solved in time because the port states are pushing their obligation to test until the very latest, and shipping owners to a large extent, feel that they have done their duty by purchasing equipment that was type approved. I think, if you look at it from a discharge point of view and what has been discharged, I don’t think there will be full compliance by September this year.

I think the whole industry is working to make sure that the systems that are installed will work better and people are trained better, but I think the fact that a third are not working on a volunteer anonymous basis is a scarily high number from my point of view.

NB: Looking at Bawat’s BaaS offering, do you think this will be a long or short-term fix to the issue?

MH: We have equipment in the US where we’ve done a couple of service jobs already, but we are focusing on Louisiana, Texas, and California, which are the major port areas in the US. We are starting up in Hamburg in May, and then trying to roll out to the major northern European countries over 2024.

Then, honestly, I think there will be room both for BaaS as we are delivering it and installation on ships. It’s not either or, I think it’s both.

I believe the treatment of invasive species in ballast water will be solved both on board the vessels and at onshore reception facilities because the diversity in shipping operations, vessel dynamics, and vessel infrastructure will mean that both options need to be present.

NB: Some port states have been giving exemptions to certain vessels and shipowners as they struggle to meet regulations. Do you think this will slow down after September, or will countries continue the practice and ‘kick the can down the road’ for implementing regulations in full?

MH: I don’t think one answer will be true across all ports, because what you do in Denmark might be different from what you do in Belgium, to what you do in Africa [sic], to what you do in Singapore. But what we can see, going towards September this year, is that port state controls are getting more and more informed about what is happening.

They have also used the last couple of years to familiarise themselves with systems and they might not have done very much port testing, but they do a lot of inspection on board vessels. They have a very good feeling about which systems are coming to port where the owners will be reporting to say: “We have a problem, or it doesn’t work, can we get an exemption?”

Regulators have an obligation. They have signed the law into effect, and they cannot continue to close their eyes.

So they have given exemptions to some extent, or asked people to go out of port and do a ballast water exchange, but we can now see ship owners coming to us and saying they have received their last exemption but are now going into the boat and cannot discharge, so can they buy our service.

I don’t think we’re going to get to September and go from full exemptions to no exemptions, it’s going to be a gradual increase, but we can see that increase is coming.

Regulators have an obligation. They have signed the law into effect, and they cannot continue to close their eyes. That’s why port state controls are very pleased that there are these land-based systems coming in because it gives them an alternative to giving an exemption or going out to do an exchange.

NB: Do you think the owners of these non-compliant ships are aware of the issue and are not bothering to address it? Or do you think a lot of them don’t realise their BWT systems are actually non-compliant?

MH: I think most of them actually try to be compliant, to be honest, but I think some of the technology that is being operated on vessels is difficult to operate, and it’s difficult to get spare parts.

If you operate a UV system with a filter and you come into a port where the port water is muddy, I don’t think it’s out of bad faith that they can’t operate it. The technology is just not fit for the environment it needs to operate. So, who’s right or wrong in that case, at the end of the day?

The shipowner says, “We bought an approved system and now it doesn’t operate where we are.” Is it then their fault? If you ask me, it is, it’s his vessel.

And this is why there is this large drive from shipowners to get something they have invented called ‘challenging water quality’ [as a concession in regulation], where they can get exemptions in ports because the water is very challenging.

Now the IMO is looking at procedures, and all these steps that they have to go through to make sure that everybody is trained, and the technology works before they can maybe get an exemption. I think they’re making it more difficult for themselves to be honest, they need to choose the technology or solution for the environment they work in.