Heavy lift construction vessel HLCV Borealis (now known as Seven Borealis) is being built by Sembawang Shipyard, in Singapore. Hull fabrication was done at the Nantong Yahua Shipyard. The crane vessel, which is owned by Subsea 7, was delivered in early 2012.

Seven Borealis is designed to be used for a range of operations, including platform installation, deck installation, spar deck installation, mooring installation, subsea installation and platform removal.

Nordic Heavy Lift placed the order for the vessel in June 2007. The keel was laid at the Nantong Yahua Shipyard in November 2008. The hull was launched in October 2009 and had arrived at Sembawang Shipyard by November 2009, where the outfitting of the vessel took place. The vessel is estimated to have cost about $460m to construct.

Nordic Heavy Lift sold the HLCV Borealis to the Acergy Group in December 2009. The ship joined the fleet of Subsea 7 following Acergy’s merger with Subsea 7 in June 2010. The ship was consequently renamed as Seven Borealis.

The Seven Borealis has an overall length of 181m, a beam of 46.2m and a molded depth of 16m. The draft of the vessel ranges between seven and 11 metres. The transit speed of the vessel is 14kt.

The vessel’s 5,500 square metre deck area has a maximum load capacity of 350t/m² and average capacity of 10t/m². The high load capacity enables the vessel to transport large modules over long distances and reduces the need for barges.

Design by Sea of Solutions and operational capabilities of the HLCV

Designed by Sea of Solutions, the Seven Borealis is based on the design of the SOC 5000 heavy lift crane vessel.

It has a single mast configuration and is the first-of-its-kind to lift 5,000mt. The vessel fitted with a DP2/DP3 system, or an eight-point mooring system.

The hull has been developed to deliver transit speeds of 13-14kt compared to the seven knots delivered by current HLCVs.

The vessel can handle subsea modules of up to 600t at a water depth of 3,000m including heave compensation. It has provisions to accommodate S-lay or J-lay pipelaying equipment. It has additional strengthening, which can be used for future pipelaying facility installations.

The vessel is used in construction and maintenance operations of offshore surface and sub-sea oil and gas field development facilities. It also has a deep water lowering capability. The vessel is suitable for subsea installation and retrieval work of deep water templates, Christmas trees and other subsea structures.

Equipment aboard the Seven Borealis vessel

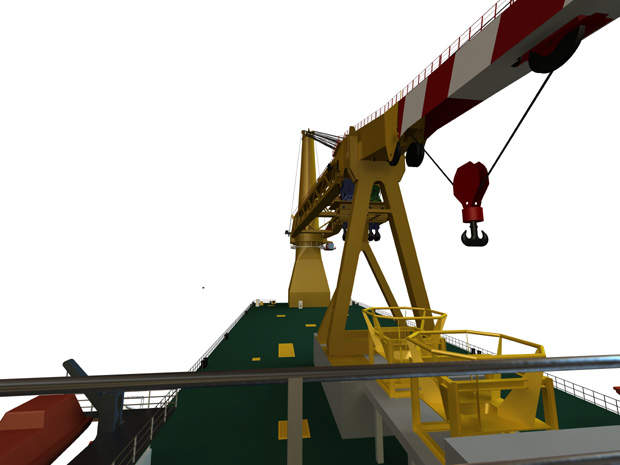

The Seven Borealis is fitted with a 5,000t revolving single mast crane, developed by Huisman Special Equipment. It has a dual main hoist that can tilt jackets.

An auxiliary hoist enables the crane to reach water depths of 1,500m. The auxiliary hoist has a 1,200t lower block and an active and passive heave compensator.

The vessel has two 40t fixed knuckle-boom cranes for general support. These cranes are located on the forward starboard deck area and the back portside of the vessel.

Accommodation on the heavy lift construction vessel owned by Subsea 7

The Seven Borealis has 120 cabins, 100 of which are two-bed cabins. It has provisions to increase capacity to 400 beds. The vessel can accommodate a crew of 52.

Propulsion of the Seven Borealis crane vessel

The vessel is powered with two 5.5MW main thrusters and equipped with four retractable thrusters. Each thruster provides an additional 3.2MW power during transit.

In addition, a bow thruster provides 2.7MW of thrust. The vessel has six 5.765MW Rolls Royce / Bergen Diesel generator sets. The propulsion system complies with DP3 requirements.