Anna Nery is a floating production storage and offloading (FPSO) vessel co-owned by Malaysian FPSO leasing company Yinson (75%) and Japanese firm Sumitomo (25%).

The FPSO was constructed at the Cosco Changxing shipyard in Shanghai, China, and is deployed in the Marlim field within the Campos basin, offshore Brazil.

Formerly known as FPSO Marlim 2, the Anna Nery FPSO is Yinson’s first asset in Brazil and its largest project to date. Petroleo Brasileiro (Petrobras) contracted Anna Nery for operations in the Marlim field from 2023 to 2048.

The project’s estimated investment is approximately $5.4bn.

The FPSO started production in May 2023.

Anna Nery FPSO development

A long-term binding memorandum of understanding (MOU) was signed between Yinson and Sumitomo in April 2018 to jointly explore and collaborate for the leasing and operation of FPSO and floating storage and offloading unit (FSO) projects. Subsequently, the two parties concluded an agreement for the charter, operation, and maintenance of the FPSO Anna Nery for the Marlim revitalisation project in April 2020.

Yinson secured the contract for the charter, operation, and maintenance of the FPSO Anna Nery from Petrobras in October 2019.

The vessel sailed from the Cosco Qidong shipyard in Jiangsu, China, to Cosco Changxing shipyard in October 2020, marking the next stage of the construction. The first steel was cut at Zhuhai Jutal Offshore Oil Services yard in October 2020.

The FPSO underwent two dry dockings and more conversion works at the Changxing shipyard until the third quarter of 2021. It then returned to the Qidong shipyard for the final phase of module lifting and integration.

The module assembly kicked off and 90% of the module review for all seven modules was completed in December 2020.

Anna Nery FPSO details

The Anna Nery FPSO project involved the conversion of the 2002-built VLCC MT Front Falcon crude oil tanker to the FPSO for operations in the Marlim field.

The platform has a production capacity of 70,000 barrels of oil per day (bopd), 250,000 barrels of liquid per day (blpd), 142 million metric standard cubic feet per day (mmscfd) of gas and a water injection capacity of 240,000 barrels of water per day (bwpd). The vessel have a storage capacity of 1.6 million barrels.

The Anna Nery FPSO is installed approximately 150km off the Brazilian coast at a water depth of 927m and is interconnected to 32 wells. The peak production period is scheduled for 2025.

Equipment onboard the FPSO

The FPSO features ABB Ability™ System 800×A control system with Select input/output (IO), an ethernet-based, single-channel IO system. All production modules are integrated into a combined integrated safety and control system (ICSS).

The vessel is installed with two reverse osmosis systems capable of producing 70,000l of fresh water and 30,000l of technical water a day. The compressed air system includes four large-capacity service and instrument air compressors with associated air dryers and filters.

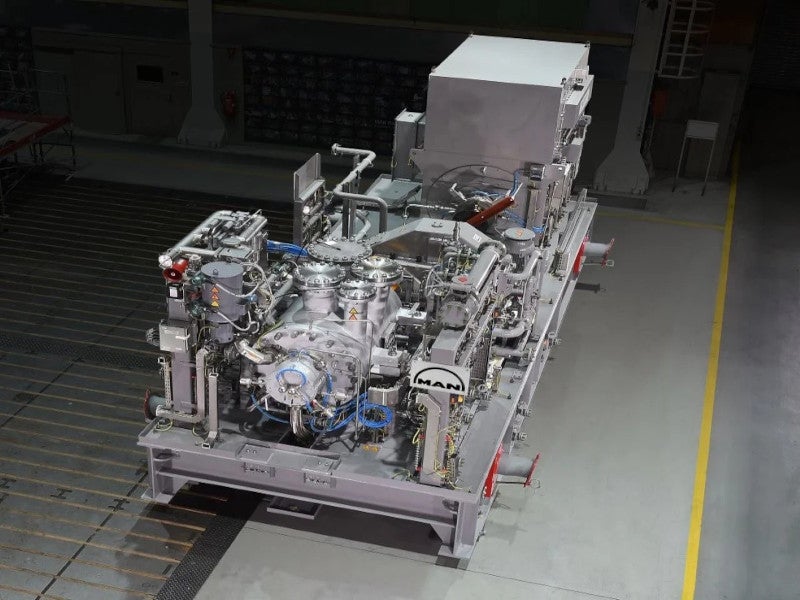

The Anna Nery FPSO is fitted with four RB-type compressor trains (two RB 56-4+4 and two RB 28-7) for gas production and export. The trains feature hydraulic, variable-speed gearboxes powered by an electric motor. Type CP200/CP128/B85 double-screw compressor trains, driven by fixed-speed electric motors, serve as vapour-recovery units.

Contractors involved

German engine and turbomachinery manufacturer MAN Energy Solutions received the contract to supply the centrifugal-compressor trains and two screw-compressor trains in June 2020.

Dutch shipbuilding company Royal IHC was awarded the contract to provide a tandem mooring and offloading system and a riser pull-in system in August 2020 while ABB was selected to deliver electrical, control, and telecommunication equipment and services.

Aragon was contracted to perform the engineering, procurement, and construction of seven modules for the gas treatment, gas compression, utilities, and flare systems, in September 2020 while TMC Compressors was chosen to supply the compressed air system.

Hatenboer-Water secured a contract to supply the reverse osmosis systems in October 2020. Frames Group was awarded the supply contract for the chemical injection systems, an electrostatic coalescer, a high-integrity pressure protection system (HIPPS), and a subsea hydraulic power unit.