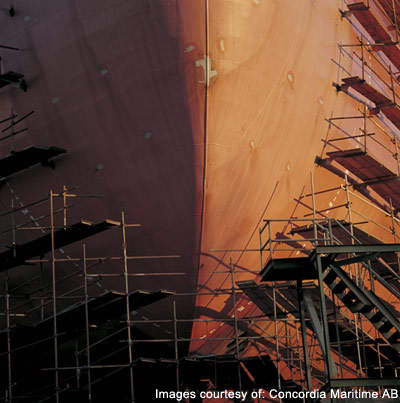

The Stena Palva is a new ice-class (Ice Class 1A) oil tanker built to Panamax specifications by the Brodosplit Shipyard (Brodosplit Brodogradiliste doo) in Split, Croatia. The tanker was part of a dual order by Concordia Maritime AB and Neste Shipping OY (50/50 partnership) in September 2004.

The Palva was named along with its sister ship Poseidon in November 2006. The Stena Poseidon was delivered in January 2007, followed by the Palva in February 2007. Both tankers (registered in Finland) have been chartered to Neste Oil for a period of ten years and will operate on a route from Finland to the US (via the Panama Canal) carrying low sulphur road fuels.

TANKER SPECIFICATION

The vessel is 228.6m long and 32.24m wide, with a draft of 20.45m and a deadweight of 75,000t. The cargo capacity is 85,500m³ (ballast water 32,819m³).

The tanker’s Ice Class 1A specification means that it is able to sail in channels where there is 1m-thick broken ice, keeping a steady speed of 5kt (ice conditions in the Gulf of Finland).

SPECIAL DESIGN

The new tanker design has several features to aid manoeuvrability and safety while negotiating the Panama Canal, sailing through ice and loading and unloading cargo.

The Palva has an extended double hull design to cover its cargo, fuel and lubricant tanks and a reinforced ‘ice belt’.

SHIP’S SYSTEMS

The Palva is powered by a MAN B&W 6S60 MC-C main engine that is built under license by the Brodosplit shipyard. The engine provides an output of 13,560kW at 105 rpm, providing a speed of 16kt on design draft in open water (80% MCR). The ship has a range of 10,000 nautical miles. The integrated navigation system for the ship was provided by Raytheon.

TANK SYSTEMS

There are six pairs of coated cargo tanks and two slop tanks installed on the vessel with a total volume of 85,672m³ when completely full. This means that six parcels of cargo oil products can be handled simultaneously.

The tanks are equipped with steam heat exchangers and stainless heating coils for the slop tanks. Each of the cargo tanks are equipped with a submerged hydraulic Framo SD300 centrifugal pump with capacity for 1,000 cbm/h and two Scanjet tank cleaning machines.

There are two pumps for ballast handling with a capacity of 1,500 cbm/h. The Moss inert gas generator system, installed as part of the fire safety system. has a capacity of 7,500 cbm/h.