Martechnic, an oil quality management solutions provider headquartered in Hamburg, Germany, has won an award in the Environmental Category in the 2024 Ship Technology Excellence Awards.

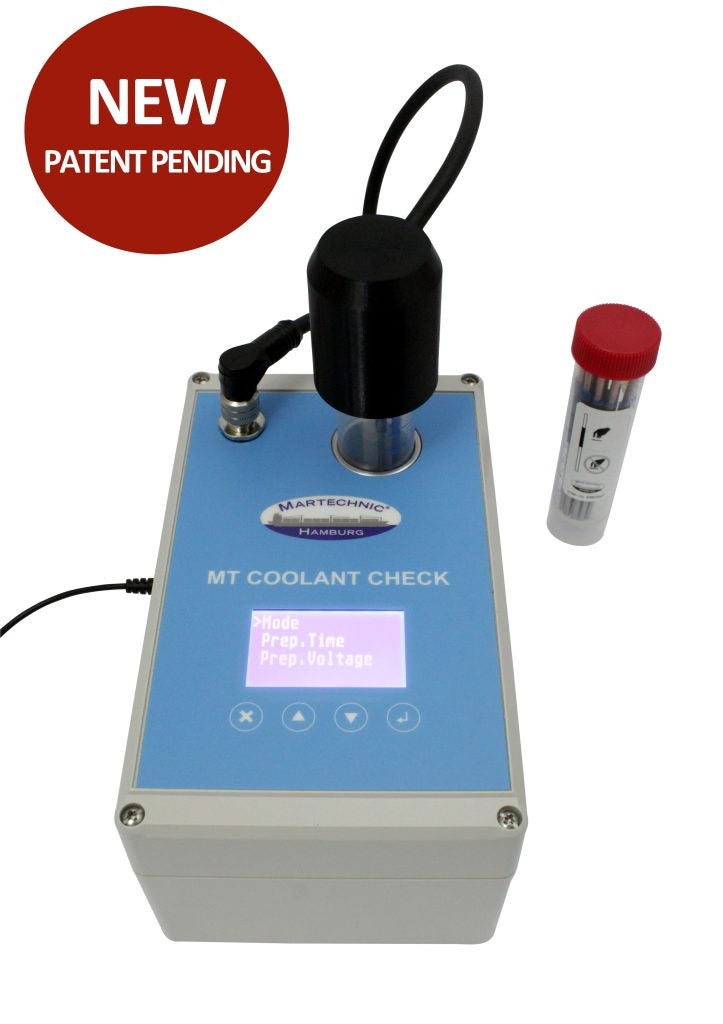

The company’s innovative, patent-pending test device MT COOLANT CHECK has been recognised for offering a non-chemical and environmentally friendly approach to engine coolant quality assessment, marking a significant stride towards sustainable predictive maintenance practices in the maritime industry.

The Ship Technology Excellence Awards celebrate the greatest achievements and innovations in the industry. Powered by the business intelligence of GlobalData, the programme provides a platform to recognise the people and companies that are driving change.

A sustainable shift in coolant testing

Traditionally, on-board engine coolant testing has relied on the complex physical and/or chemical analyses of individual parameters (chlorides, nitrite additives, pH etc.) to evaluate the sufficiency of the anti-corrosion effect of the coolant in use. Different chemicals, predominantly classified as hazardous products, are utilised for the analyses. Martechnic’s own test kits COOLANT AND LUBE OIL and MT COOLING WATER CHECK have been part of this conventional approach.

Instead, the test device MT COOLANT CHECK offers the environmentally friendly alternative measurement method. The engine coolant quality and its anti-corrosive protection is determined by means of the electrotechnical apparatus, with constant (corrosion-resistant) and working/changeable (corrosion-prone) electrodes in a simulated engine cooling system.

No chemicals are required at all. The device, thereby, eliminates the use of harmful substances and reduces environmental risks, especially to marine ecosystems.

Technical excellence and environmental responsibility

The MT COOLANT CHECK simplifies the testing process by analysing water-based coolants with just one single measurement through a single coolant sample in a simulated cooling system, delivering results in just 15 minutes. All the evaluation is carried out fully automatically.

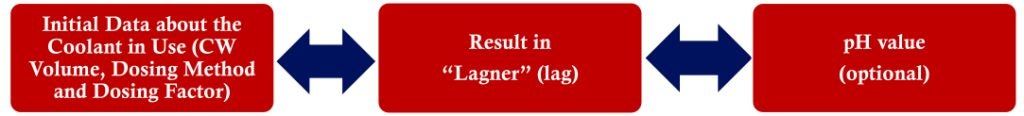

Furthermore, the company has introduced the “Lagner” (lag) as a new unit of measurement. This value is central to assess the remaining corrosion protection of the engine coolant in use.

If the anti-corrosive effect of the coolant is insufficient, the device can calculate the precise dosing rate of the chemical additive required to add, if any, by entering the following available data provided in the manufacturer’s coolant specifications:

- CW (cooling water) volume in m3

- Dosing method: liquid or powder

- Dosing factor: l/m3 or kg/m3

To replace the use of disposable pH test strips, the pH value of the coolant can be also measured through the integration of a separate optional pH electrode into the sensing head of the test device MT COOLANT CHECK.

On the basis of the data received, the maintenance crew on-board a vessel receives a clear recommendation to further actions if required.

Eco-friendly manufacturing for a greener future

Martechnic employs sustainable manufacturing practices for the MT COOLANT CHECK device. The electrodes, made from steel and stainless steel, are far less resource-intensive to produce than the chemicals and plastic bottles of traditional test kits. The materials used in the device are easily recyclable, contributing to a circular economy and reducing the overall environmental impact.

Enhancing predictive maintenance and reducing waste

The MT COOLANT CHECK‘s role in advancing predictive maintenance practices has been a key factor in its award recognition. By offering precise and timely maintenance recommendations, the device helps to avoid unnecessary coolant changes and wastage. The long-lasting electrodes also contribute to waste reduction, making the solution not only environmentally friendly, but also cost-effective for ship operators.

Furthermore, by replacing a series of individual tests, the device saves valuable time and resources, allowing for more efficient maintenance schedules.

Company Profile

Oil Quality Management: Condition Monitoring of Fuel, Lube & Hydraulic Oil and Cooling Water

More Than 25 Years of Tradition and Innovation

Martechnic was established in 1997. Since its founding, the company has become a leading expert in oil quality management. A small family-owned business has succeeded to secure its international recognition and a solid niche market position of technical solutions for condition monitoring of fuel, lube, and hydraulic oil. In March 2022 Martechnic celebrated its 25th corporate anniversary.

A cornerstone of the business’s philosophy and practice has been the combination of two principles: tradition and innovation. Using the benefits of past knowledge and experience, Martechnic focuses on innovative technology and offers its customers oil and cooling water test analysis equipment for on-site application.

The company designs, develops and manufactures a wide range of high-quality products: oil test devices and oil test kits, intelligent oil sensor technology, cooling water testing equipment, oil sampling bottles and ultrasonic cleaning equipment. A global network of Martechnic’s partner companies provides for 24-hour customer service, quick order processing and worldwide delivery.

Company’s Vision and Mission

For over 25 years Martechnic’s oil analysis solutions have been an effective tool to support smooth running, optimal and reliable performance as well as cost-effective maintenance of on-board machinery, engine, and equipment. The adoption of oil condition monitoring practices or in-service oil testing allows engine operators to routinely measure, monitor and analyse crucial oil parameters directly on board a vessel. Thereby any off-specification issues (e.g., degradation of the oil quality or abnormal wear) or changes in the oil condition (e.g., contamination) can be detected before an actual problem occurs. Such an early-warning mechanism enables adequate preventive maintenance actions: continuous information on engine performance can help fixing relatively minor problems to avoid possible costly engine failures, major damages, and uncontrolled downtimes.

Successful implementation of oil condition monitoring programs can also help to comply with international norms and standards of environmental protection aiming at minimising environmental impact, supporting sustainable development, and saving precious resources.

Areas of Expertise

- Oil Test Devices and Test Kits

- Oil Analysis with Intelligent Sensor Technology

- Cooling Water Testing Equipment

- Oil Sampling

- Ultrasonic Cleaning Equipment

Contact Details

Martechnic GmbH

Adlerhorst 4

D-22459 Hamburg

Germany

Tel: +49 (040) 853 128 0