Dutch shipyard Royal Bodewes will continue its relationship with Damen Marine Components (DMC) with a two-year contract covering vital equipment for four new vessels.

The works will begin immediately, with the installation of bridge controls including steering hardware for a Ro-Ro ship nearing completion at the Royal Bodewes shipyard in Hoogezand, north Netherlands.

In the longer term DMC will install similar equipment and hardware to three 9,000DWT general cargo ships known as Bodewes Eco Traders.

Along with steering gear and bridge controls, the cargo ships will be fitted with propeller nozzles by DMC.

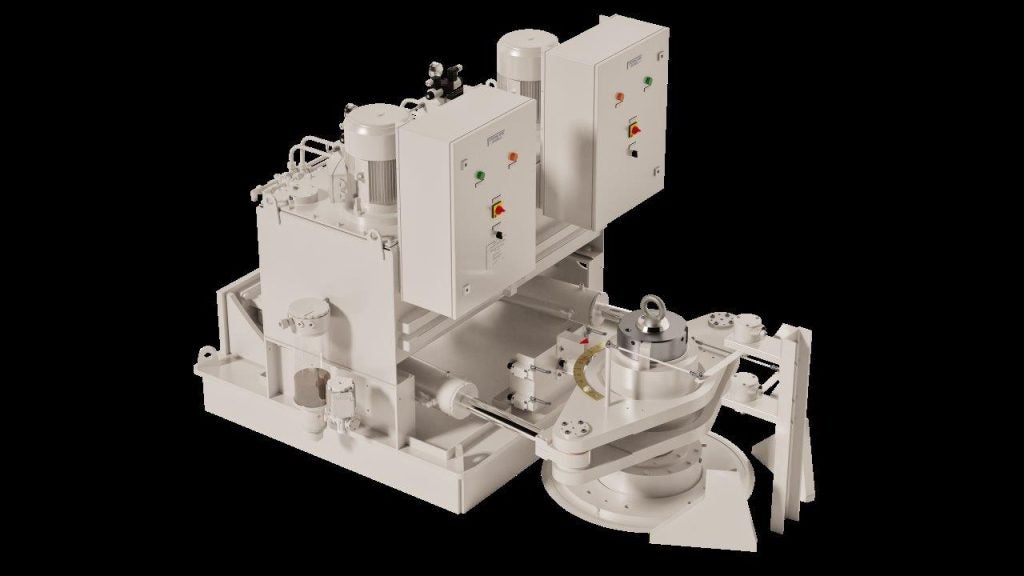

The componentry provider said a key development in its steering system would be installed on all four ships, giving electric-hydraulic rudder control.

“We have designed our steering gear with a plug-and-play philosophy. This means that we manufacture and install the equipment onto a skid in our own factory in Hardinxveld-Giessendam, the Netherlands,” explained DMC sales manager Marnix de Bruijn.

“There it can be FAT tested, witnessed by a class surveyor as required before it is placed on board the ship. All Royal Bodewes has to do is to connect the hydraulic and electrical supply – this saves a lot of time and energy on board,” de Bruijn added.

Both companies hailed their ongoing relationship and explained the contract also covered ongoing consultation.

“We have had a good working relationship with Damen Marine Components for a long time. We have worked with them on numerous projects and their excellent price-quality ratio is one of the reasons for that,” said Royal Bodewes business development manager Martijn Beunk.

“We are proud to be working with Royal Bodewes on this Ro-Ro ship and the three coastal cargo vessels. We aim to help them wherever possible by aligning our products and operations to match their shipbuilding strategy, which is highly efficient, and look forward to our continued collaboration,” De Bruijn added.