The Devil Cat is one of Incat Tasmania’s fast ferry wave-piercing catamarans and was built at their Hobart shipyard in 1997. It has a capacity of 900 passengers, 240 cars and the ability to maintain fully loaded service speeds of 43 knots, or 80km/h. At lightship condition, Devil Cat has achieved 50.2 knots, or 93km/h. The catamaran is operated by TT Line Company Pty Limited on their ferry service from Melbourne, Australia, across the Bass Strait to Tasmania.

DESIGN

Devil Cat is constructed from marine-grade aluminium alloys, particularly, the 5383-H116 alloy. The aluminium superstructure is supported on vibration damping mounts. The catamaran design is characterised by long slender waterborne hulls, each subdivided into eight watertight compartments, with very little buoyancy at the bow. As each hull encounters a wave it tends to ‘pierce’ through it rather than ride over it.

Passenger comfort has been increased significantly with the introduction of the 91m wave-piercing catamaran. Excluding hull shape and form, which contribute significantly to a comfortable ride, part of the improvement can be attributed to the enhancement of the Maritime Dynamics Inc. ride control system. The system consists of an active trim tab mounted at the transom of each hull, which provides trim and motion dampening. Forward active ride control T foils will also be fitted to maximise the effect of the MDI system.

The air-conditioned electronics room, located under the bridge, can be accessed via a private stairwell leading from the bridge or, alternatively, from the vehicle deck. The area conveniently houses many unmanned electronic subsystems, previously located in the wheelhouse.

FACILITIES

The main passenger deck (tier 2) contains two lounges, separated by an amenities block housing toilet facilities, a baby changing room and a small crew mess with shower facilities. On the forward side of the atrium, Café 91, a duty free store and a ships office are found. Tier 2 seating consists entirely of aircraft-style seats, supplied by the Australian-based company, Maxton Fox.

PROPULSION

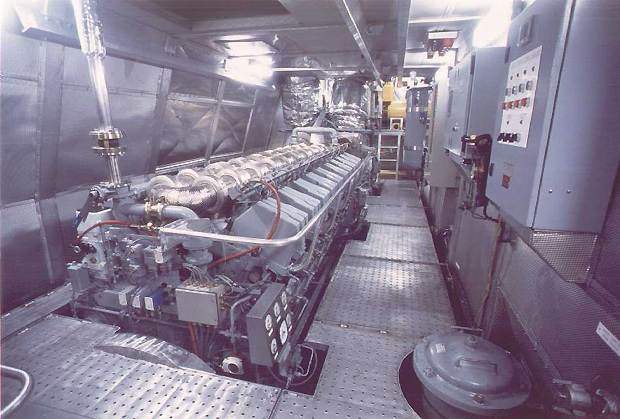

The vessel is powered by four Ruston 20 RK270 conventional medium-speed diesel engines, which provide 7,080kW (9,500hp) each. Each engine drives a transom mounted waterjet (Lips LJ145D) through a Renk ASL60 reduction gearbox. Along with steering and reversing, the custom-designed Lipstronic jet control system provides the option of thrust vectoring and autopilot.

Two Caterpillar generators in each hull (four 230kW in total) feed associated independent main switchboards that are can disconnect in an emergency. The standard AC supply and distribution system is 415/240V, three phase.

AUTOMATION AND CONTROL

The navigation and communication equipment is supplied by Electrotech Australia. The ship’s position is provided by a Decca MX400B, a six-channel GPS with a built-in DGPS Beacon Receiver. Primary navigation is performed by the two Decca BridgeMaster II 250 Series radars. The Navigator’s radar uses a 30kW S-Band transceiver transmitting at 3GHz with a 12ft scanner. The Captain’s radar is an X-Band 25kW unit transmitting at 9.4GHz into a 6ft scanner. Both scanners rotate at 48rpm to maximise target detection when the vessel is travelling at high speed.

A Skipper GDS101 with a 50kHz transceiver provides optimum sea-bottom detection, even at speeds greater than 40 knots.

Long-range communications in the 2MHz to 30MHz band is provided by a Skanti TRP7200 Transceiver. Two Skanti VHF3000 25W transceivers operating in the frequency range 155MHz to 163MHz provide line-of-sight, short-range communications. The Navigator’s VHF3000 is interfaced to a DSC3000 DSC Controller, which enables DSC functions in the VHF band. A McMurdo MCM406A Emergency Position Indicating Radio Beacon will automatically float free and transmit on 406MHz in the case of shipwreck.